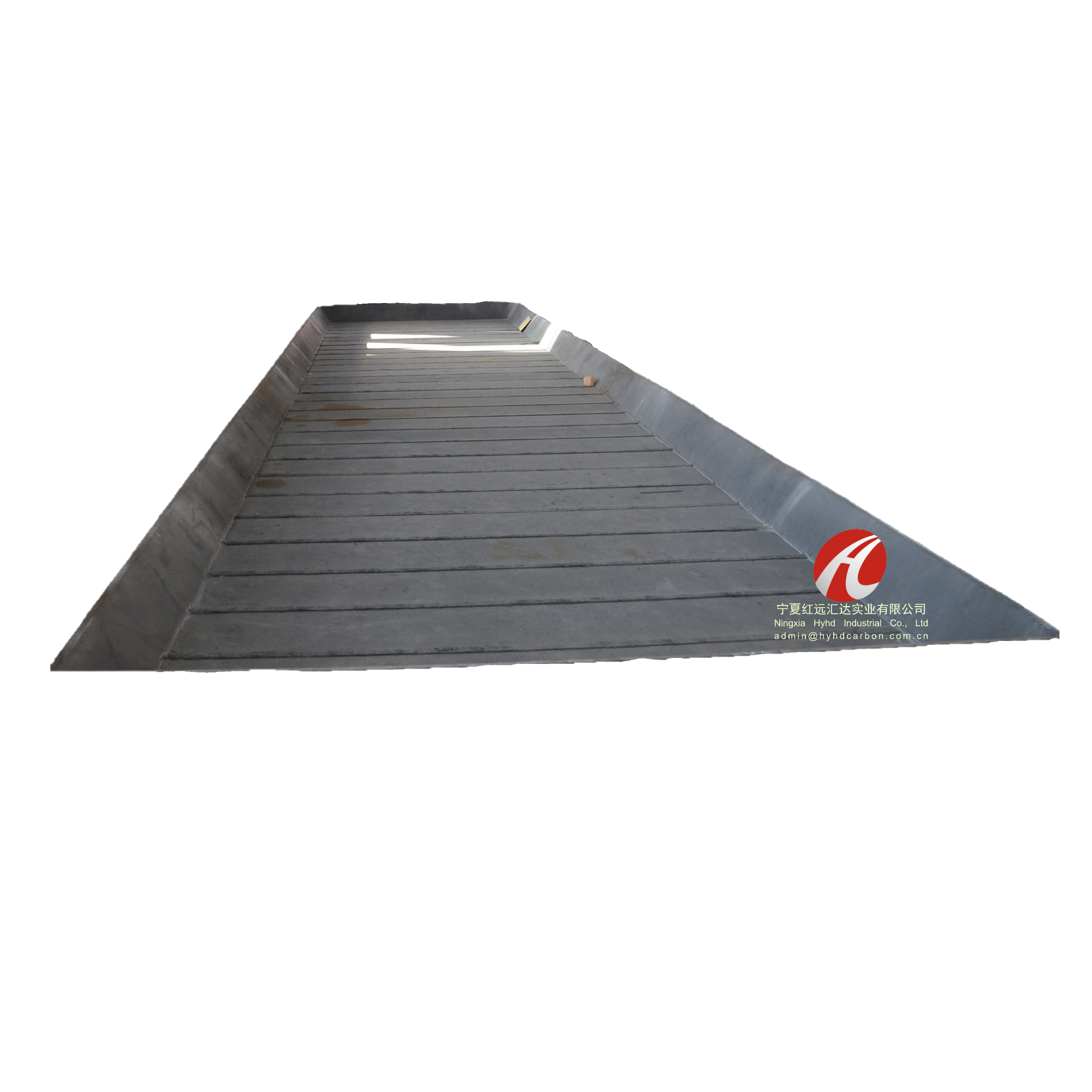

Cold Ramming Paste -GSLD-1

Item No.: 01

Cold Ramming Paste GSLD-1 has been developed for using in aluminium electrolysis cells.It has a very low concentration of benzo[a]pyrene equivalent compounds,

and the exposure during installation is very limited in the recommended temperature range of ap

INQUIRY